Project Description

ABOUT THE PRODUCT

Since their market launch, the EXITFLEX abrasive Flap disc has successfully taken the place of the grinding disc in many areas of surface finishing.

The performance of the abrasive Flap disc, with its fan-shaped radial an arrangement of cloth grinding flaps, far exceeds that of other abrasive products.

EXITFLEX abrasive flap discs are made of zirconia alumina, ceramic, or aluminium oxide coated flaps fastened to glass fiber-reinforced or plastic backing plates. The even arrangement of the flaps guarantees high flexibility, constant high grinding performance and low vibrations.

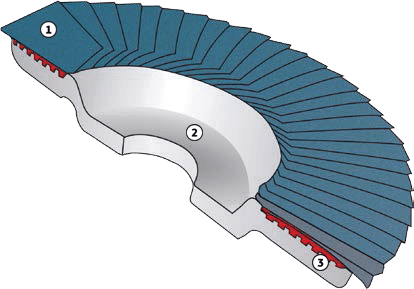

PRODUCT STRUCTURE

The three abrasive flap disc components are perfectly integrated to achieve maximum performance.

Grinding flaps (1)

EXITFLEX has developed special coated abrasives for its abrasive mop discs. The grinding tool is perfect for use with a high-speed angle and corresponding applications. This ensures top grinding performance long service life.Backing plate (2)

EXITFLEX uses two different backing plate types to produce abrasive mop discs. The first one is the most popular on the market made of glass fibre; the second one is made of plastic.Glue (3)

The glue (adhesive) is the joint between the backing plate and the grinding flaps. It ensures that the grinding flaps cannot come off the backing plate if used properly. It also ensures safety far above the guidelines of the ANSI directives and the ENI2413 safety standard.

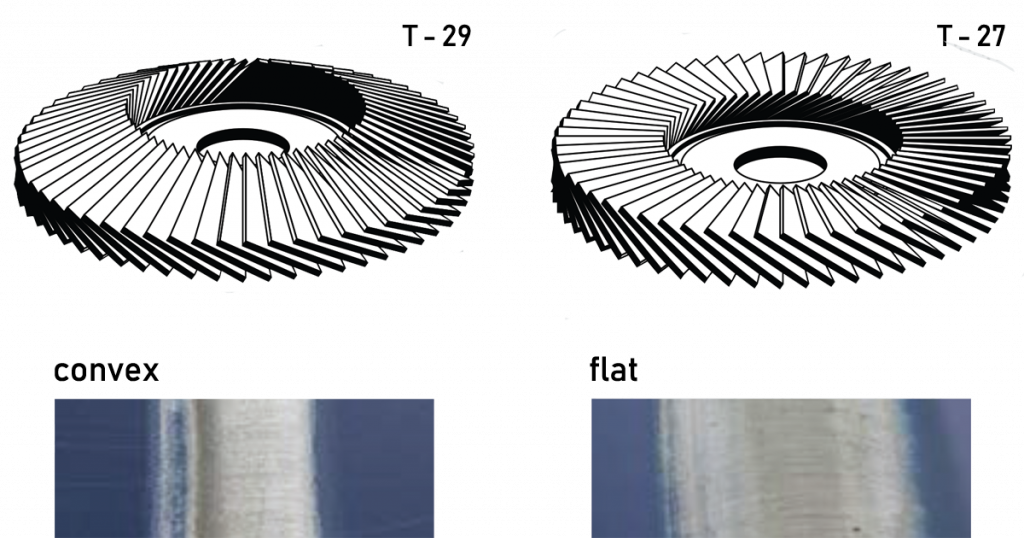

Form

The convex abrasive flap disc grinds a narrower surface than the flat abrasive flap disc. The more selective use of the convex disc achieves a greater stock removal rate per time unit as compared to the flat flap disc. The convex abrasive flap disc is particularly suited to working on edges and welded seams. The flat disc is primarily used for flat and surface grinding.